In the Mpower Studio, we believe in showing students they have gifts, talents, skills and abilities that they never thought they had before. We give students the ability to showcase their gifts through a highly engaging, maker-centered learning environment. With a variety of tools and equipment, we allow students to make the invisible, visible.

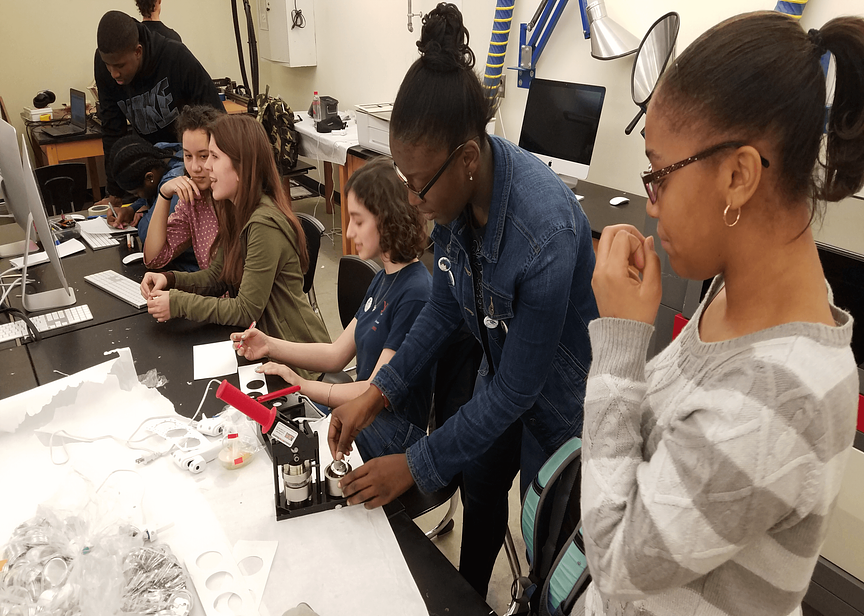

Our school makerspace has become a place full of innovation. From rapid prototyping, manufacturing, and a design-centered, project-based learning curriculum to providing students with unique STEM opportunities, all students are collaborating together to make their ideas become a reality. Many students start their own endeavors such as building t-shirt businesses, making gifts for friends and family, taking leadership roles and building a team to help make their ideas visible. Students are not just learning about all the unique opportunities to collaborate, they are learning how to design and lead their lives with a sense of meaning and purpose.

Every sophomore and freshman student enrolls in Intro to Engineering and Applied Engineering and these classes are connected with our makerspace. By the end of the school year, almost 300 students are directly involved in the world of making. There are days during the week where any student can stay after school and take advantage of “open shop” hours where they are free to design and make anything they want to.

Students are realizing when you have a vision with a deep sense of impact and purpose that alone will carry you through obstacles and challenges. With our space being connected to a class, there is equality for all students to take full advantage of the idea of making the invisible visible. All students see how the makerspace can be adaptable to other areas of school and life. After being in the makerspace for a class, students have completed other subjects’ projects. English teachers let their students create videos and drama teachers allow their students to create scenes from stories. Students have even created props for theater shows.

During sophomore year, our students are required to complete a personal project and many students take advantage of our space. One student is currently designing and laser cutting residential plans and taking advantage of 3D printing to create interior furniture and equipment. Other students start small businesses and sell products to the community. Another student is making and selling shirts to fundraise for school events.

We want all students regardless of background, race, or socioeconomic status to have equal opportunities and take advantage of all the STEAM, design-centered, and problem-based learning challenges so they are prepared for an ever changing technical global society. Allowing our students access to a makerspace gives opportunity to apply learning through real world challenges, to present learning in different ways, to adapt to new situations, and to take action on new ideas and innovations.